The uni product range is divided into two separate groups:

Chains

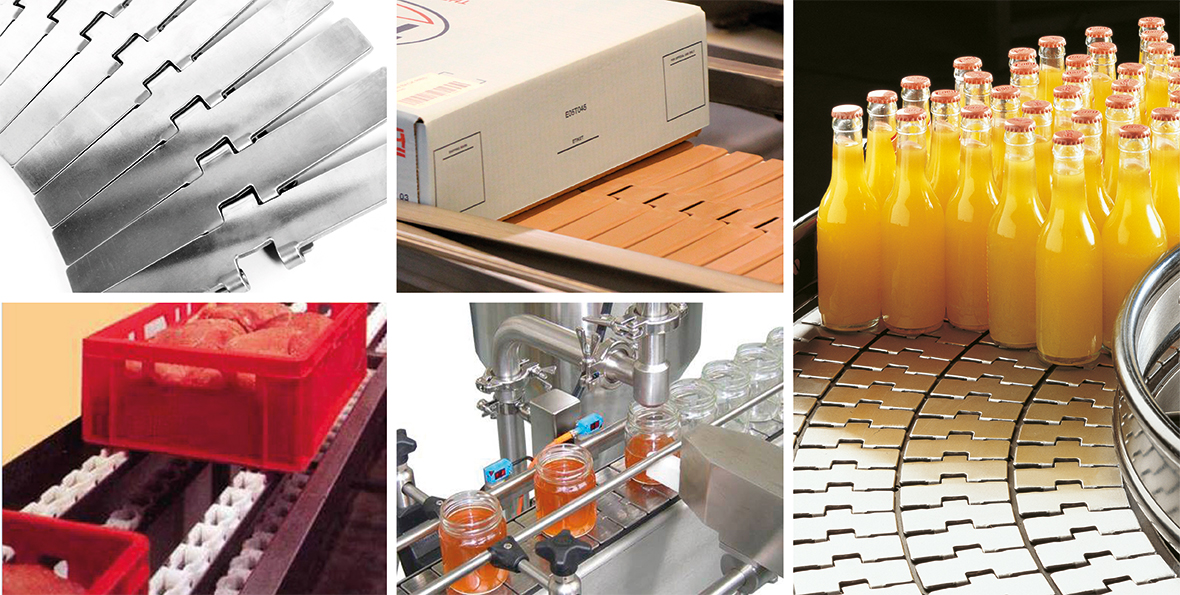

Chains are made of hard plastic or steel modules that are connected to each other by pins.

These modules come in various materials and shapes.

Modular Belts

Modular belts are made of hard plastic modules that are connected to one another by pins. By putting modules together in a brick-lay pattern, almost any belt width can be achieved.

Modules come in various materials and shapes.

For all chains and modular belts a selection of sprockets and accessories is available.

Chains

Chains consist of metal or plastic links connected by pins. Like other belts, chains are used for conveying products The following series are available:

- uni Slat Top Chains (plastic and steel)

- uni Snap-On Chains

- uni Flex Chains

- uni Special Chains

Both straight running and side flexing chains are available. Chains are industry-standard products, used in many applications. Steel chains are used for the transportation of glass bottles in breweries and of hot pans in the baking industry and other food applications. uni Flex Chains are used to move large and/or heavy products on parallel multi-lanes.

Belts

Modular belts consist of links which can be arranged in a brick-lay pattern, so is it possible to make very wide and long belts. The links are connected by pins. Belts have many hinges that pull the load and, therefore, a belt gets stronger as it gets wider.

In general, these belts have a long lifetime, and the modular design allows you to replace damaged pieces without removing the entire belt.

Many different series of modular belts are available - all developed for various purposes.

Strength, material, pitch (i.e., distance from pin to pin) and other factors can vary, as can belt surfaces and surface apertures. Modular belts are either straight running or side flexing.

Sprockets

For modular belt conveyors, sprockets are crucial components.

Modular belts are moved with positive drive. The power and torque are transmitted from sprockets to belt via the engagement between the belt and the teeth in the sprockets. Positive drive also has the advantage that the belt stays in position and does not move sideways.

A range of sprocket sizes are available for all modular belt series. The sprockets at the drive end must be fixed to the shaft:

- Round bores with keyways

- Square shafts and square bores in the sprockets